Description

|

Technical Parameters |

|||

|

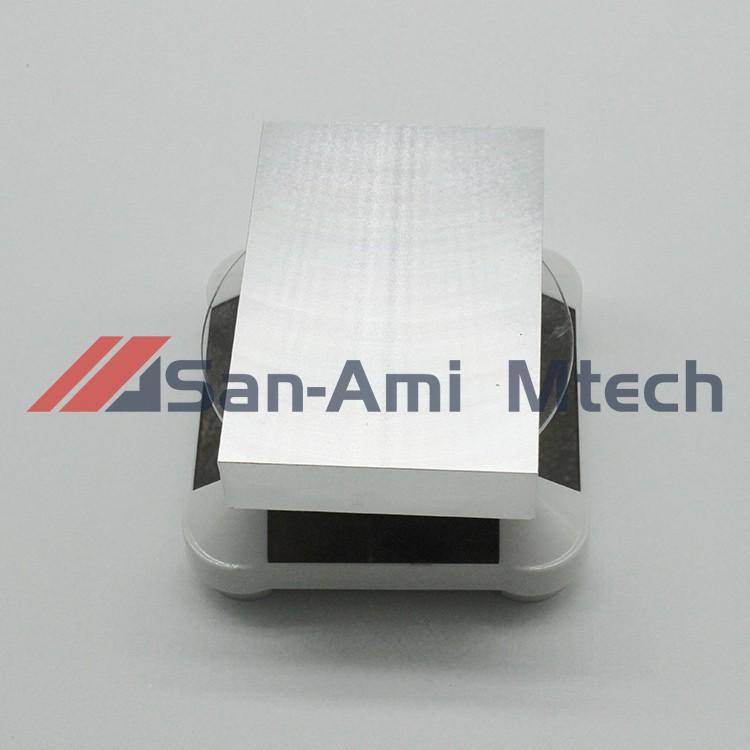

Material categories |

Magnesium sputtering target |

Molecular formula |

Mg |

|

CAS No |

7439-95-4 |

Purity |

99.9%-99.999% |

|

Molar mass |

24.305 |

Density |

1.738g/cm³ |

|

Melting point |

650 °C |

Boiling point |

1091 °C |

|

Solubility (water) |

Insoluble in water, soluble in alkali, hydrochloric acid, sulfuric acid |

||

Product Overview:

Magnesium belongs to the group IIA alkaline earth metal element on the periodic table, with a relative atomic mass of 24.305. It has a silver white luster and slight ductility. Magnesium has a low density and a strong ionization tendency.

In air, a thin oxide film forms on the surface of magnesium, making it difficult for air to react with it. Magnesium reacts with alcohol, acid, and hot water to produce hydrogen gas. Powdered or banded magnesium emits a strong white light when burned in air. When heated at high temperature in nitrogen, magnesium will generate magnesium nitride; Magnesium can also react strongly with halogen; Magnesium can also be directly combined with vulcanization. The detection of magnesium can be analyzed using EDTA titration. The ignition point is about 733.15 degrees Kelvin.

We can provide customized services according to needs, welcome all customers to inquire.

Product Application:

Manufacture of aluminum alloy, die casting (forming alloy with zinc), desulfurization treatment in steel production, Kroll process to prepare titanium.

Magnesium metal can be used in molten salt metal thermal reduction process to produce rare metals.

Because magnesium is lighter than aluminum, magnesium aluminum alloy containing 5%-30% magnesium is light, has good mechanical properties, and is widely used in aviation and aerospace.

Magnesium is easy to oxidize and can be used to make reducing agents for many pure metals. It can also be used for flash lights, aspirators, fireworks, flares, etc.

Adding trace magnesium to molten pig iron, ductile iron is obtained after cooling, which is tougher and wear-resistant than ordinary iron.